The CSS Alabama Dishes

July 2008

By Caitlin Shaffer, MAC Lab Conservator

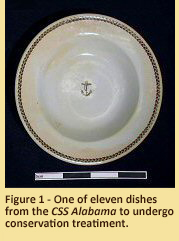

In 2007, the Maryland Archaeological Conservation Laboratory undertook the conservation of artifacts recovered from the shipwreck of the CSS Alabama, one of the most well-known Confederate warships. The artifacts included eleven ceramic dishes belonging to the tableware set used on the ship (Figure 1). Although the dishes were in remarkably good condition, they required conservation treatment to ensure that they did not deteriorate.

In 2007, the Maryland Archaeological Conservation Laboratory undertook the conservation of artifacts recovered from the shipwreck of the CSS Alabama, one of the most well-known Confederate warships. The artifacts included eleven ceramic dishes belonging to the tableware set used on the ship (Figure 1). Although the dishes were in remarkably good condition, they required conservation treatment to ensure that they did not deteriorate.

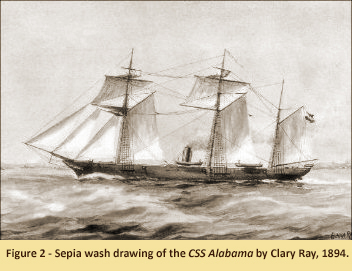

The CSS Alabama (Figure 2) was built in Liverpool, England in 1862 for the Confederate government, and its main occupation was to cause damage to Union shipping endeavors. During the ship's nearly two years at sea, the Alabama captured and burned more than sixty enemy ships, including a dozen New England whalers and eight commerce ships in the first few months alone (Shomette 1973:227). In June 1864, the Alabama entered the harbor of Cherbourg, France to make repairs and restock supplies. Meanwhile, the Union's USS Kearsarge, which had been pursuing the Alabama, began to patrol the mouth of the Cherbourg harbor and waited for the Confederate ship to emerge. The Alabama met the Kearsarge on June 19, 1864, and after approximately one hour of battle, the Alabama was destroyed and sank in about 200 feet of water (Naval Historical Center 2007).

The CSS Alabama (Figure 2) was built in Liverpool, England in 1862 for the Confederate government, and its main occupation was to cause damage to Union shipping endeavors. During the ship's nearly two years at sea, the Alabama captured and burned more than sixty enemy ships, including a dozen New England whalers and eight commerce ships in the first few months alone (Shomette 1973:227). In June 1864, the Alabama entered the harbor of Cherbourg, France to make repairs and restock supplies. Meanwhile, the Union's USS Kearsarge, which had been pursuing the Alabama, began to patrol the mouth of the Cherbourg harbor and waited for the Confederate ship to emerge. The Alabama met the Kearsarge on June 19, 1864, and after approximately one hour of battle, the Alabama was destroyed and sank in about 200 feet of water (Naval Historical Center 2007).

The Alabama wreck was discovered in 1984, and since then it has been jointly investigated by the U.S. Naval Historical Center and the French Ministry of Culture under the Franco-American CSS Alabama Scientific Committee (CSS Alabama Association USA 2004).

The eleven dishes that were recovered from the wreck site, and which are currently undergoing treatment at the MAC Lab, were made by Davenport, a pottery located in Staffordshire, England, about fifty miles from where the Alabama was built.

The eleven dishes that were recovered from the wreck site, and which are currently undergoing treatment at the MAC Lab, were made by Davenport, a pottery located in Staffordshire, England, about fifty miles from where the Alabama was built.

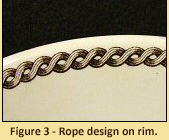

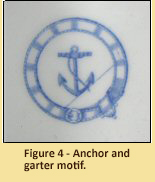

Davenport was in production from 1793 to 1887 and made a wide range of porcelain, stoneware, earthenware, and glass goods (Godden 1999:226). A late 19th century advertisement in the Pottery Gazette describes some of their products, "Davenport…Ironstone ware, plain and decorated…suitablefor barracks, clubs, hotels and ship uses" (Godden 1971:107). The Alabama dishes are made of "ironstone," a durable, white earthenware clay, and the nautical theme of the dishes indicate that they were designed specifically to be used on ships . The rim of each dish is encompassed by an intertwined rope (Figure 3), and in the center of each dish is an anchor; two of the dishes also have a garter motif surrounding the anchor (Figure 4). The patterns on two of the dishes are blue and the other nine are brown. Maker's marks on the underside of the dishes (Figure 5) show that they were made in 1860.

Davenport was in production from 1793 to 1887 and made a wide range of porcelain, stoneware, earthenware, and glass goods (Godden 1999:226). A late 19th century advertisement in the Pottery Gazette describes some of their products, "Davenport…Ironstone ware, plain and decorated…suitablefor barracks, clubs, hotels and ship uses" (Godden 1971:107). The Alabama dishes are made of "ironstone," a durable, white earthenware clay, and the nautical theme of the dishes indicate that they were designed specifically to be used on ships . The rim of each dish is encompassed by an intertwined rope (Figure 3), and in the center of each dish is an anchor; two of the dishes also have a garter motif surrounding the anchor (Figure 4). The patterns on two of the dishes are blue and the other nine are brown. Maker's marks on the underside of the dishes (Figure 5) show that they were made in 1860.

The Alabama dishes went through several steps during their conservation treatment (Figures 6-8). First, the conditions of the artifacts were recorded through photographs and written descriptions. A course of treatment, which included desalination, surface cleaning, stain removal, and drying was then designed and implemented. Desalination, or removal of salts, is especially important when working with ceramics, as salts from burial or marine environments can be absorbed into clay bodies and cause permanent damage when changes in humidity cause the salts to dissolve, migrate, and recrystallize (Newton and Logan 1997:3). If this process occurs repeatedly, the glaze or surface of an object can be forced apart. Since the Alabama dishes were retrieved from a saltwater environment, they required desalination. This was accomplished by soaking the dishes in baths of deionized water that were monitored and changed as salt leeched out of the ceramic body until the solution contained less than five parts per million of salt. The next step, surface cleaning, removed deposits from the surfaces of the dishes, and was carried out using various tools and brushes. Stain removal also aimed to remove or lessen deposits, although from the interior body of the ceramic rather than just the surface. Several types of chemicals were used to reduce the iron staining that was evident on the Alabama dishes, including a chelating agent, which contains molecules that bond with metallic ions (Museum of Fine Arts, Boston 2008) and allow the ions to be drawn out of the ceramic body. The final step in the conservation treatment was air-drying. Although this was a simple step, it was imperative that the dishes remain wet until the stain removal was complete, as drying could have caused the deposits to become more difficult to remove. From beginning to end, the conservation of the CSS Alabama ceramic dishes took nearly six months.

All images courtesy of the U.S. Naval Historical Center

| References |

|

| CSS Alabama Association USA |

| 2004_ |

Artifact Recovery. Electronic document, http://www.css-alabama.com/challenge.html, accessed June 10, 2008. |

|

| Godden, Geoffrey A. |

| 1971 |

The Illustrated Guide to Mason’s Patent Ironstone China. Praeger Publishers, London. |

|

| Godden, Geoffrey A. |

| 1999 |

Godden's Guide to Ironstone Stone and Granite Wares. Antique Collectors' Club Ltd., Woodbridge, Suffolk, England. |

|

| Museum of Fine Arts, Boston |

| 2008 |

MFA Boston: Material Record. Electronic document, http://cameo.mfa.org/materials/record.asp?key=2170&subkey=2028, accessed June 13, 2008. |

|

| Naval Historical Center |

| 2007 |

CSS Alabama. Electronic document, http://www.history.navy.mil/branches/org12-1.htm, accessed June 10, 2008. |

|

| Newton, Charlotte and Judy Logan |

| 1997 |

Care of Ceramics and Glass. Canadian Conservation Institute Notes. 5/1. |

|