Curator's Choice 2017

Pig Iron Bar with Runners from Antietam Furnace Iron Works

June 2017

By Gareth McNair-Lewis, MAC Lab Conservatior Technician

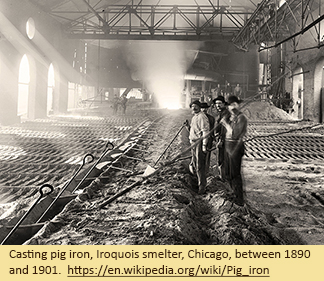

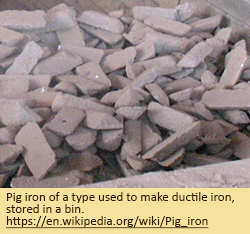

Several pig iron bars have been conserved over the years at the Maryland Archaeological Conservation Laboratory in St. Leonard, Maryland. What is pig iron? Pig iron is the intermediate product of smelting iron ore with a high-carbon fuel such as coke. Sometimes charcoal and anthracite have also been used as fuel. The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter (a mixture of iron ore and other materials prepared for smelting) and limestone (https://en.wikipedia.org/wiki/Pig_iron). Pig iron and cast iron have a higher carbon content than wrought iron. In order to produce quality wrought iron the excess pig iron slag had to be removed. The impurities and high carbon content of pig iron made it brittle and unmalleable for blacksmiths to fashion into quality goods. But in this state pig iron was useful in making cast iron objects such as frying pans, cooking pots, fences and railings. Molds would be shaped in the sand and molten iron would be carried by ladles and poured into the patterns thus producing cast iron items ((Eggert 2017 - https://www.engr.psu.edu/mtah/essays/pigiron.htm).

Several pig iron bars have been conserved over the years at the Maryland Archaeological Conservation Laboratory in St. Leonard, Maryland. What is pig iron? Pig iron is the intermediate product of smelting iron ore with a high-carbon fuel such as coke. Sometimes charcoal and anthracite have also been used as fuel. The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter (a mixture of iron ore and other materials prepared for smelting) and limestone (https://en.wikipedia.org/wiki/Pig_iron). Pig iron and cast iron have a higher carbon content than wrought iron. In order to produce quality wrought iron the excess pig iron slag had to be removed. The impurities and high carbon content of pig iron made it brittle and unmalleable for blacksmiths to fashion into quality goods. But in this state pig iron was useful in making cast iron objects such as frying pans, cooking pots, fences and railings. Molds would be shaped in the sand and molten iron would be carried by ladles and poured into the patterns thus producing cast iron items ((Eggert 2017 - https://www.engr.psu.edu/mtah/essays/pigiron.htm).

Pig iron was made by smelting iron ore into transportable ingots of impure high carbon content, after which further steps would be needed before useful wrought iron was achieved. Smelting and producing pig iron was known to the ancient Egyptians and spread around the Mediterranean to Greece. Western Europe discovered the process in the Late Middle Ages (1325-1500).

Pig iron was made by smelting iron ore into transportable ingots of impure high carbon content, after which further steps would be needed before useful wrought iron was achieved. Smelting and producing pig iron was known to the ancient Egyptians and spread around the Mediterranean to Greece. Western Europe discovered the process in the Late Middle Ages (1325-1500).

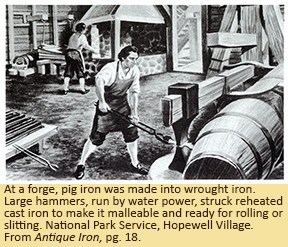

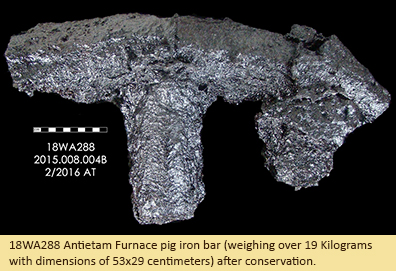

When the pig iron bars cooled they were then taken to the forge where they were reheated and forged into wrought iron bars by pounding them with large hammers run by water power. This process made them more malleable while lessening the carbon content. Blacksmiths were now able to work with this new wrought iron and make many useful objects (Herbert and Schiffer 1979).  Four pig iron bars from the Steward Shipyard site (18AN817) in Anne Arundel County, Maryland have been conserved at the MAC Lab, along with several from Antietam Furnace (18WA288), also known as Mt. Aetna Iron Furnace, in Antietam, Washington County, Maryland. The town of Antietam was the site of large iron-working facilities from the mid-eighteenth to late nineteenth centuries. Ore and wood for charcoal were found in the nearby South Mountain area. Pig iron was the major product used in various forges in Western Maryland (mht.maryland.gov).

Four pig iron bars from the Steward Shipyard site (18AN817) in Anne Arundel County, Maryland have been conserved at the MAC Lab, along with several from Antietam Furnace (18WA288), also known as Mt. Aetna Iron Furnace, in Antietam, Washington County, Maryland. The town of Antietam was the site of large iron-working facilities from the mid-eighteenth to late nineteenth centuries. Ore and wood for charcoal were found in the nearby South Mountain area. Pig iron was the major product used in various forges in Western Maryland (mht.maryland.gov).

One of the pig iron bars from Steward Shipyard bears the name of “LEGH” from the Legh Masters Furnace (1765-1767) north-east of Baltimore. Another larger example has the raised letters “N*C* K*H*L* 1776” (Thompson 2005). Some Antietam Furnace pig iron bars have raised lettering and some do not.

One of the larger Antietam Furnace pig iron bars (weighing over 19 kilograms with dimensions of 53x29 centimeters), was oddly shaped, with what are called runners. The object looked like no other pig iron bar that I had conserved before. It was irregularly shaped with two right angled extensions and a pitted concave side and a smoother convex side.

One of the larger Antietam Furnace pig iron bars (weighing over 19 kilograms with dimensions of 53x29 centimeters), was oddly shaped, with what are called runners. The object looked like no other pig iron bar that I had conserved before. It was irregularly shaped with two right angled extensions and a pitted concave side and a smoother convex side.

During the production of pig iron, the molten iron would flow out through a hole at the bottom of the furnace and branch out into a row of troughs dug into the sand floor (Forgeng 2007). This branching structure formed in sand had many ingots at right angles to a central channel or runner resembling a litter of piglets being suckled by a sow (https://en.wikipedia.org/wiki/Pig iron). These molds leading off at right angles from the main molds or “sow molds” are a series of smaller ones, side by side, called “pig molds” (https://www.engr.psu.edu/mtah/essays/pigiron.htm).

| References |

|

| Eggert, Gerald |

| 2017 |

Where Do Little Pig Irons Come From? https://www.engr.psu.edu/mtah/essays/pigiron.htm. Accessed May 22, 2017. |

|

| Forgeng, Jeffrey |

| 2007 |

Daily Life in Stuart England. Greenwood Press. Westport, CT. |

|

| Herbert, Peter and Nancy Schiffer |

| 1979 |

Antique Iron: Survey of American and English Forms, Fifteenth through Nineteenth Centuries. Schiffer Publishing Ltd., Atglen, PA . |

|

| mht.maryland.gov |

| 2017 |

Antietam Iron Furnace site and Antietam Village. 2003-2015. Maryland Historical Trust. Accessed May 22, 2017. |

|

| Thompson, Bruce |

| 2005 |

Steward Shipyard Site (18AN817). Pig Iron. Personal Communication |

|

| Wikapedia |

| 2017 |

Pig Iron. https://en.wikipedia.org/wiki/Pig_iron. Accessed May 22, 2017. |

|